The right material for your wear problem:

MINERAL CAST

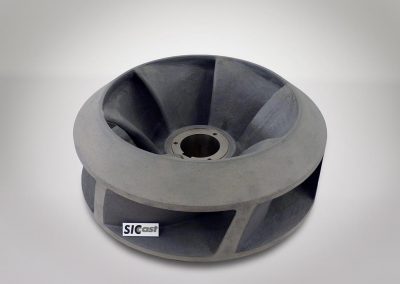

SICcast EP 135

SICcast EP 135 consists of silicon carbide, which can be mixed with a hot-curing epoxy resin (EP) under vacuum and cast without pressure in moulds. The temperature-controlled casting process keeps shrinkage very low. Parts from 1 kg to 8 tons can be produced with a high accuracy in high-precision casting. Required connection fits are processed to the finished size with diamond tools, and threaded connections are cast in directly with corrosion-resistant cast parts.

SICcast EP 135 can be used at up to 135 °C.

The Components

SiC

Silicon carbide is a synthetic mineral produced in an elaborate industrial procedure. The element silicon (Si) is present as a raw material in the form of silicon oxide (SiO2 quartz sand) and will form a carbon compound with petroleum coke under high temperature (+ CO). The result is silicon carbide (SiC) with a hardness according to Mohs at 9.7 (diamond=10). This is broken to different screen lines. The setup of different screen lines permits a high packing density of the grain.

Epoxy resin

Polish of the material in scale 500:1

1. Binders and very small SiC grains

2. The lighter areas show lower SiC-grains

3. Binder entered into SiC-grain

4. Ground, polished SiC-grain

The Result

A metal-free, anti-magnetic, sound-muffling and vibration-dampening material with diamond-like hardness.

Due to the chemical binding of the epoxy resin, this material is ductile and thus comparatively temperature shock and impact resilient.

The Benefits

- The high wear resilience due to the high silicon carbide share in excess of 80%

- The lower brittleness due to the bound epoxy resin

- The high chemical resilience of the SiC and EP resin (pH 0-12)

Coating Material

SIConit is a silicon carbide composite material for repair and protection of surfaces exposed to erosion corrosion, abrasion and / or corrosion (pH value 0 – 12) at temperatures up to 100 °C.

YOU HAVE A WEAR PROBLEM - SICcast develops customized solutions for you!

PROFESSIONAL, INNOVATIVE & COMPETENT IN EVERYTHING WE DO

Do you have a problem with erosion corrosion, abrasion and / or corrosion?

Are you looking for a particularly resilient material?

Would you like to reduce your repair costs?

Would you like to additionally protect your present part against wear and increase its service life?

Get In Touch

SICcast Mineralguss GmbH & Co. KG

Location

Wilhelm-Düchting-Straße 22

58453 Witten/Germany

Phone

+49 2302 969 200

Open Hours

Office:

Mon - Fri: 8am - 5pm (CET)

Factory:

Mon - Fri: 6am - 2pm (CET)